One of the most useful business office supplies today is certainly the carbonless copy paper. With its placement between sheets of paper you can create a carbon i.e. duplicate form of invoices, receipt books or other business forms. By using it you can provide a perfect copy which is both clean and legible copy of a quote, receipt or other business transaction. They are biodegradable and stain-free which makes them very easy and efficient for work. Carbonless copy paper has undergone different phases since its invention to become the type that is today, suitable to use with laser or ink jet printers. Nevertheless, its benefits are numerous and vouch for its functionality. Let’s go through some background facts and its benefits.

Background Facts

The exact date of the invention of carbonless copy paper remains uncertain, but the first documented use is in the 19th century, in 1806, when Ralph Wedgwood, an Englishman, issued a patent for his “stylogrphic writer.” In the same period, an Italian man, Pellegrino Turri invented a typewriting machine in Italy so he perfected his form of carbon paper in order to successfully operate his machine. The interesting part is that the paper was invented just to get to their other planned goals which was to help blind people write through the use of a machine.

Further Development

Wedgwood was the man who continued developing the idea of using the paper as a method of making copies of business documents, business letters or private letters. His technique involved using a metal stylus on a thin transparent sheet of paper over one of the carbon sheets so that he could get a black copy of another sheet. This technique was picked up by a company which developed it further, but it was more acceptable for businessmen in that time to sent out letters and documents written in ink so that they could avoid forgery that might appear as a result of the copywriting process. Even though the letter-copying book became a standard procedure in the 1870s, the court did not allow its use.

Overseas Events

It was in 1823 when Curys P. Dakin from Massachusetts made carbon paper similar to the one Wegwood started making, and sold it exclusively to the Associated Press. Many years later, the commercial potential for copying office documents became hugely evident. The year of 1870 saw the first major sale of carbon paper and it was for the United States War Department.

Ingredients of the Copy Paper

At first, carbon paper was manufactured by hand. People used a mixture of a pigment carbon black and oil in naphtha and this mixture was applied to sheets of paper by the use of a wide brush. Later, hot wax was used to replace the oil that created a mess. The use of hot wax opened opportunities for the carbon paper to be made in a variety of qualities.

Carbon Transformed into Carbonless Paper

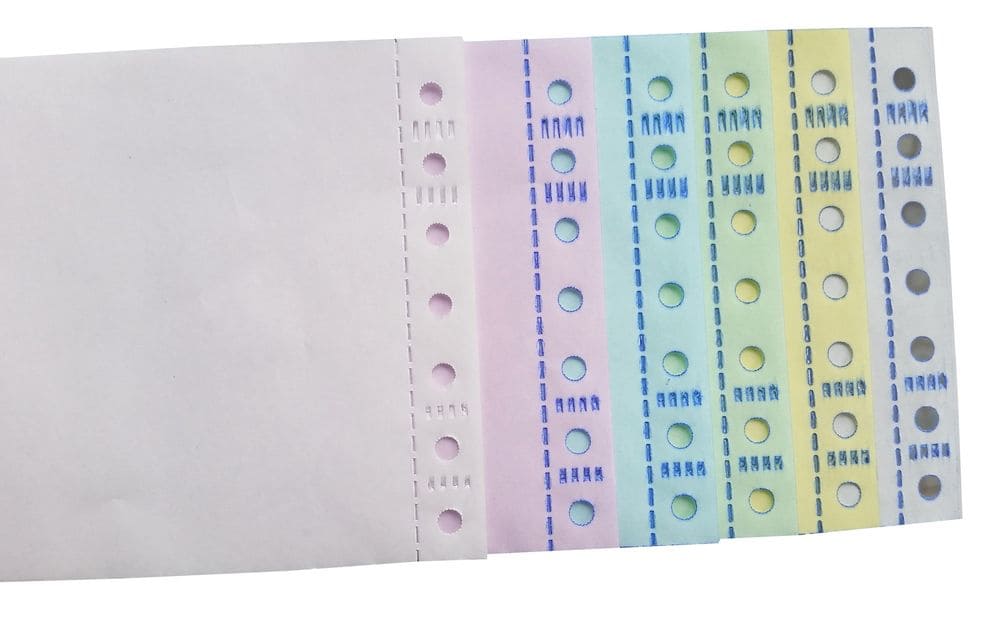

With the invention of the photocopier, the demand for carbon paper decreased to a large extent. However, the National Cash Registry Company developed carbonless copy paper in 1954. The process of using this new type of paper relied on the pressure of a pen or typewriter to induce a chemical reaction between different coatings on adjacent sheets of paper.

Benefits of Carbonless Copy Paper

Apart from being very cos-effective, the carbonless copy paper has a plethora of benefits. One of those benefits is speed which allows the user to create more than one copy of the forms instantly. Secondly, it is accurate as it eliminates transcription errors. Then, it prevents alteration and any change to a copy is evident immediately, so it provides security. Furthermore, it provides clarity as it gives a sharp copy image. Moreover, it is clean as it prevents text image from smearing or rubbing off. Finally, It is also versatile because it enables reverse printing or colour coding to suit business needs.